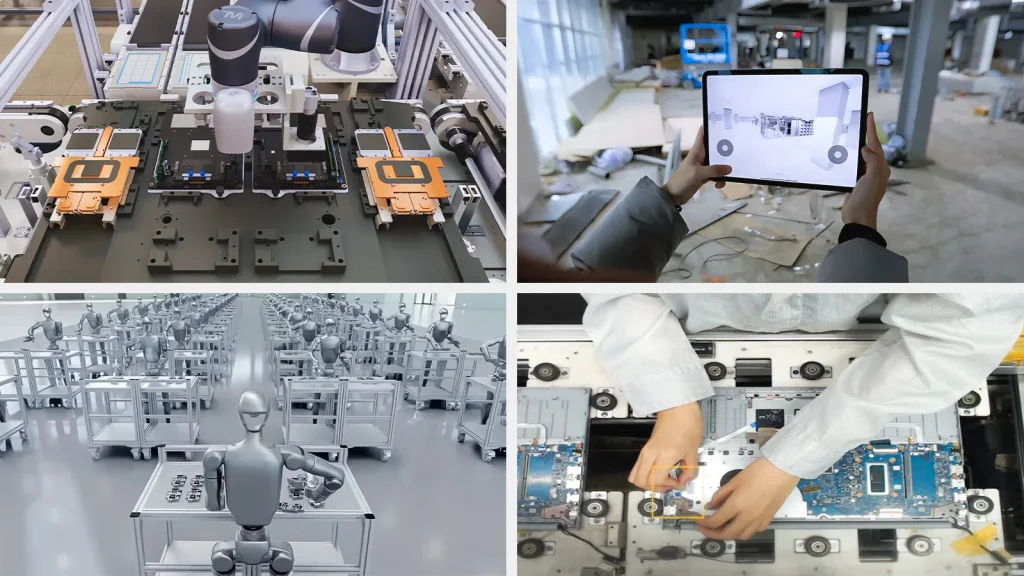

So, NVIDIA at the COMPUTEX 2025 expo has one clear message to the professional and industrial players – They have been expanding their Omniverse ecosystem with brand new tools and ways to help create industrial agentic AI as well as digital twins easier than ever.

With participation by various big names across the world and those particularly from Taiwan like Foxconn, TSMC, Wistron, Delta, and more, they have been achieving extraordinary progress and innovative ways to make their respective businesses more resilient and smart.

Here are some quick examples and brief details on how they do it.

Foxconn

- Built their own Fii Digital Twin platform using Omniverse, OpenUSD, and Siemens tools.

- Simulates robot cells, assembly lines, and full factory layouts with connection to material control systems to test how robots and humans move and work together.

- Training robot arms and humanoid bots with NVIDIA’s Isaac Lab and GR00T models to handle tasks like assembly and cable insertion.

- Utilizing Omniverse to simulate thermal environments and optimize POD rooms with Cadence and NVIDIA PhysicsNeMo – which is 150x faster than traditional thermal modeling.

- Deploying video analytics agents for real-time production monitoring using NVIDIA Metropolis and the VSS blueprint.

TSMC

- Working with a startup to turn flat 2D factory plans into immersive 3D layouts using Omniverse to help detect equipment collisions and analyze system interdependencies before construction even starts.

- Uses NVIDIA’s cuOpt and Isaac Lab to auto-generate complex piping systems in seconds.

- Vision-language models to improve defect detection and classification during QC.

- Runs NVIDIA CUDA-X libraries and GPUs for everything from lithography (via cuLitho) to full semiconductor process simulations.

Wistron

- Their WiDT platform is powered by Autodesk, Cadence, Microsoft, and NVIDIA AI tools.

- Connects to shopfloor machines and uses real-time data for optimization dashboards.

- Robotic arms now assemble parts 12 seconds faster thanks to Isaac Sim testing.

- Creating video training content using NVIDIA’s Cosmos Tokenizer to boost worker onboarding and SOP compliance.

Other IT Brands

- Wiwynn is using Omniverse-based twins to simulate production, deploy cobots, and refine quality control.

- Pegatron’s PEGAVERSE and PEGAAi platforms handle everything from predictive maintenance to visual AI agents for worker training. They’ve already cut labor costs by 7% and reduced defects by 67%.

- Kenmec and MetAI built a full digital twin of the Chief Smart Logistics Center using Omniverse to test warehouse automation with real-time logic and physics.

- GIGABYTE is connecting IoT data into their twins to flag production anomalies visually.

- Quanta Cloud Technology is using Omniverse for better factory planning and remote design collaboration with customers and suppliers.

Robotics-focused Investment

- Delta Electronics is simulating and training all types of industrial robots using Isaac Sim, and they’re launching a training center soon to teach others how to use their DIATwin platform.

- Techman Robot is working with Volkswagen’s Transparent Factory to train AI cobots that ride GESSbot AMRs. Thanks to Isaac Sim, they’ve cut programming time by 70% and boosted productivity by 20%.

- Foxlink is giving their industrial robots generalized AI using the Isaac GR00T N1 model.

- Solomon is helping Inventec inspect servers 8x faster and with 50% fewer errors using Isaac Manipulator and CUDA-X.

- Kudan is combining its 3D SLAM tech with Isaac Perceptor in NexAIoT’s NexMOV-2 AMRs for better navigation in messy environments.

- MSI is using Jetson AGX Orin modules for warehouse bots doing pick-and-place and handling.

- Adata and Advantech are rolling out hospital-cleaning AMRs with Isaac Sim and Jetson Orin, cutting deployment time by 70% and making the process 3x faster.

- Ubitus is even training G1 humanoids to deliver medical samples to help hospitals deal with labor shortages.

On the other hand, ready-to-use templates for building AI factories are never been simpler through the latest expansion of the Omniverse Blueprint service, currently available in preview.

Basically, they’re giving engineering teams a more powerful set of tools to create digital twins of AI factories – and this expansion is pulling in some serious new partners.

They’ve now got Delta Electronics, Jacobs, and Siemens onboard, adding to the original lineup of Cadence, Schneider Electric (with ETAP), and Vertiv. The idea is to unify the simulation of all the nuts and bolts – power, cooling, networking – that go into designing and running an AI factory. Think of it like a super-detailed virtual copy of an entire facility that lets teams test and optimize everything before even laying a single brick.

What’s powering all this is NVIDIA’s reference architecture for their GB200 NVL72 AI factories, built using OpenUSD (Universal Scene Description). That means they can pull together complex 3D models and simulation data into one place, making it way easier to design infrastructure that’s efficient, powerful, and resilient.

Another big step forward is the SimReady standardization workflow. Initially created for NVIDIA’s own use, it’s now available industry-wide. It sets clear standards for building simulation-ready models, which is super helpful for anyone trying to build their own digital twin for AI infrastructure.

Schneider Electric, Vertiv, and others are also contributing “SimReady” assets – these are ready-to-go 3D models designed specifically for simulation. They help create a more complete and functional digital twin. ETAP and Cadence are key players here too, providing thermal and power simulations through their platforms. That allows engineers to plan for energy demands and cooling needs well before any physical build begins.

Industry Partner Support

As for the powerful partners who have worked with NVIDIA in this regard, we have Siemens, whose already building 3D models that follow the blueprint, Delta’s providing models of their own equipment, and Jacobs is running tests to fine-tune the workflow. Because it’s all based on OpenUSD, the simulations are spot-on. You get realistic views of how everything will perform, right down to how heat moves through the system.

ETAP’s CEO, Tanuj Khandelwal, even pointed out how this is essential for managing the massive energy demands of AI workloads. It’s about squeezing out as much efficiency as possible, right from the start. Cadence’s Ben Gu echoed that, saying their digital twin integration with Omniverse is transforming how these AI factories are designed and run.